- GLASS PRODUCTS:

- Tubes and rods

- Glass beads and insulators

- Policapillary rods and policapillary cones

- Fiber-optic units

- Microstructural and photonic-crystal fibers

- Flat multi-channel tubes (capillaries)

- Cylindrical microlenses

- Microchannel plates (MCP)

- Experimental products (complicated glass structures)

- EQUIPMENT:

- Glass products pressing machine

- Glass products flame treatment machines

- Glass products chemical treatment lines and posts

- Equipment for glass and glass products cutting

- Machines for glass products drawing from a glass block

- Machines for preforms redrawing into glass products

- Glass structures sintering machines

Special manufacturing equipment for glass industry:

MACHINES FOR PREFORMS REDRAWING INTO GLASS PRODUCTS

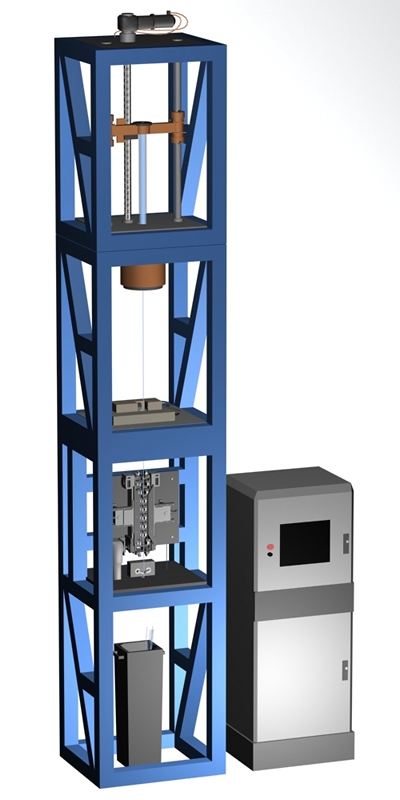

TEGS Ltd. fabricates machines for redrawing of glass items with different cross-section shapes.

They can not only draw single channel tubes (preforms) but also batches of single and multi-channel tubes and rods with different cross sections. The initial (macro) and final (micro) cross sections of structures are geometrically similar. Several cycles of glass items redrawing allow reducing the structure components dimensions up to 0.2 mcm with the accuracy of 0.5-1.0%.

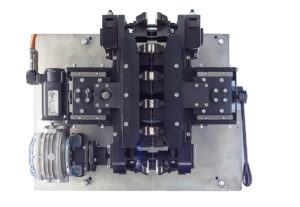

Glass products high accuracy is provided by the use of cylindrical chambers with independent heating elements (heating zones), designated for creation of the desired temperature distribution along the whole length and angular coordinates of the cylinder and high accuracy electric motors providing for the specified drawing rate.

Automatic adjustment is performed on the basis of results of measurements made by a two axis laser gage.

The constituent part of our equipment is automatic control systems including electronic control systems and personal computers.

|

The machine technical specifications:

The operation process is schematically shown in the video film . |

en

en ru

ru zh

zh es

es de

de