- GLASS PRODUCTS:

- Tubes and rods

- Glass beads and insulators

- Policapillary rods and policapillary cones

- Fiber-optic units

- Microstructural and photonic-crystal fibers

- Flat multi-channel tubes (capillaries)

- Cylindrical microlenses

- Microchannel plates (MCP)

- Experimental products (complicated glass structures)

- EQUIPMENT:

- Glass products pressing machine

- Glass products flame treatment machines

- Glass products chemical treatment lines and posts

- Equipment for glass and glass products cutting

- Machines for glass products drawing from a glass block

- Machines for preforms redrawing into glass products

- Glass structures sintering machines

Special manufacturing equipment for glass industry:

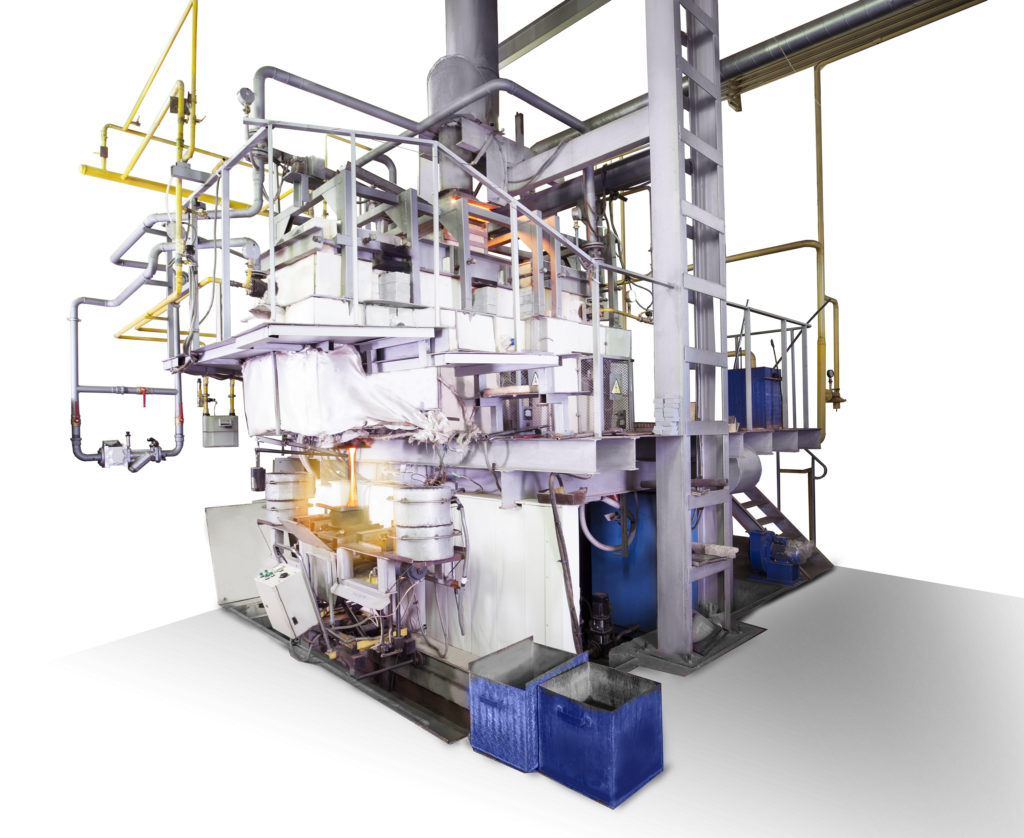

GLASS MELTING FURNACE

TEGS Ltd. owns a technology solution and has significant experience of operation of a batch, gas and electric glass melting furnace with the glass drainage vertically downwards through a ceramic tube. We can adapt this furnace for your production process, besides we can fabricate, install and adjust it at your company.

- Capacity is 1000 kg;

- Yielding capacity is 200 kg per 24 hours period;

- Glass melting maximum temperature is up to 1600°C;

- The necessary energy sources:

- Natural gas (gas pressure is 4 kPa, gas flow rate is up to 5000 m³ per month;

- Electric power is an AC three-phase mains (voltage is 380 V / 50 Hz, power consumption in the operating mode is 60 kWt/h).

- Circulation water supply system for molybdenum electrodes cooling.

- Air for burning is ventilating.

- Molybdenum electrodes quantity is 6 pcs.;

- The furnace overall dimensions are 2780х1650х1500 mm.

The advantage of this furnace is high yield capacity and small power consumption.

en

en ru

ru zh

zh es

es de

de